Kayayyaki

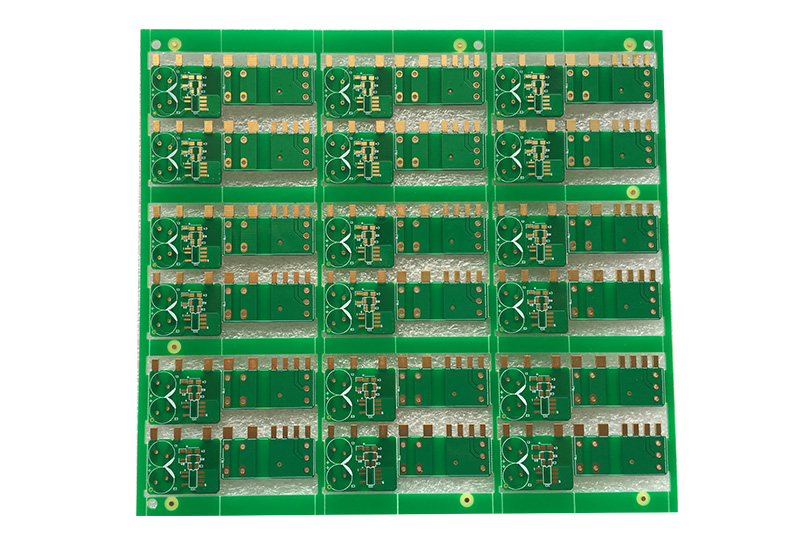

Edge plating 6 Layer pcb don babban allon IOT

| Yadudduka | 6 yadi |

| Kaurin allo | 1.60MM |

| Kayan abu | Farashin FR4tg170 |

| Kaurin jan karfe | 1/1/1/1/1/1 OZ (35um) |

| Ƙarshen Sama | ENIG Au Kauri 0.05um;Ni Kauri 3um |

| Min Hole (mm) | 0.203mm cike da guduro |

| Nisa Min Layi (mm) | 0.13mm |

| Sararin Layi Min (mm) | 0.13mm |

| Solder Mask | Kore |

| Launin Almara | Fari |

| sarrafa injina | V-maki, CNC Milling (routing) |

| Shiryawa | Jakar anti-a tsaye |

| E-gwajin | Binciken Flying ko Fixture |

| Matsayin karɓa | Saukewa: IPC-A-600H |

| Aikace-aikace | Kayan lantarki na mota |

Kayan samfur

A matsayin mai ba da kayan fasaha na PCB daban-daban, kundin, zaɓuɓɓukan lokacin jagora, muna da zaɓi na daidaitattun kayan da za a iya rufe babban bandwidth na nau'ikan PCB iri-iri kuma koyaushe ana samun su a gida.

Hakanan ana iya biyan buƙatun wasu ko na kayan musamman a mafi yawan lokuta, amma, dangane da ainihin buƙatun, ana iya buƙatar kusan kwanaki 10 na aiki don siyan kayan.

Yi tuntuɓar mu kuma ku tattauna bukatunku tare da ɗayan tallace-tallacenmu ko ƙungiyar CAM.

Daidaitaccen kayan da aka riƙe a hannun jari:

| Abubuwan da aka gyara | Kauri | Hakuri | Nau'in saƙa |

| Yadudduka na ciki | 0,05mm | +/- 10% | 106 |

| Yadudduka na ciki | 0.10mm | +/- 10% | 2116 |

| Yadudduka na ciki | 0,13mm | +/- 10% | 1504 |

| Yadudduka na ciki | 0,15mm | +/- 10% | 1501 |

| Yadudduka na ciki | 0.20mm | +/- 10% | 7628 |

| Yadudduka na ciki | 0,25mm | +/- 10% | 2 x1504 |

| Yadudduka na ciki | 0.30mm | +/- 10% | 2 x1501 |

| Yadudduka na ciki | 0.36mm | +/- 10% | 2 x7628 |

| Yadudduka na ciki | 0,41mm | +/- 10% | 2 x7628 |

| Yadudduka na ciki | 0,51mm | +/- 10% | 3 x 7628/2116 |

| Yadudduka na ciki | 0,61mm | +/- 10% | 3 x7628 |

| Yadudduka na ciki | 0.71mm | +/- 10% | 4 x7628 |

| Yadudduka na ciki | 0,80mm | +/- 10% | 4 x 7628/1080 |

| Yadudduka na ciki | 1,0mm ku | +/- 10% | 5 x7628/2116 |

| Yadudduka na ciki | 1,2mm | +/- 10% | 6 x7628/2116 |

| Yadudduka na ciki | 1,55mm | +/- 10% | 8 x7628 |

| Prepregs | 0.058mm* | Ya dogara da shimfidawa | 106 |

| Prepregs | 0.084mm* | Ya dogara da shimfidawa | 1080 |

| Prepregs | 0.112mm* | Ya dogara da shimfidawa | 2116 |

| Prepregs | 0.205mm* | Ya dogara da shimfidawa | 7628 |

Cu kauri don yadudduka na ciki: Standard - 18µm da 35 µm,

akan buƙatar 70 µm, 105µm da 140µm

Nau'in Abu: FR4

Tg: kusan.150°C, 170°C, 180°C

εr a 1 MHz: ≤5,4 (na al'ada: 4,7) Ana samun ƙarin akan buƙata

Tari

Babban ƙa'idar tari na Layer 6 zai kasance gabaɗaya kamar ƙasa:

Babban

· Ciki

· Kasa

· Iko

· Ciki

· Kasa

Tambaya&A Yadda Ake Gwajin Ƙaƙwalwar bangon Ramin Da Ƙididdiga masu alaƙa

Yadda za a gwada ramin bangon bango da ƙayyadaddun bayanai masu alaƙa?Katangar rami ta kawar da haddasawa da mafita?

An yi amfani da gwajin cire bangon rami a baya don sassan ramin don biyan buƙatun haɗawa.Gwajin gabaɗaya shine a siyar da waya akan allon pcb ta ramuka sannan a auna ƙimar fitar da ma'aunin tashin hankali.Dangane da gogewa, ƙimar gabaɗaya suna da girma sosai, wanda ke sa kusan babu matsala a aikace.Bayanin samfur ya bambanta bisa ga

zuwa buƙatu daban-daban, ana ba da shawarar yin la'akari da ƙayyadaddun bayanai masu alaƙa da IPC.

Matsalolin rabuwar bangon rami shine batun rashin mannewa mara kyau, wanda gabaɗaya ya haifar da dalilai guda biyu na gama gari, na farko shine ɗaukar ƙarancin desmear (Desmear) yana sa tashin hankali bai isa ba.Sauran shi ne tsarin plating na jan karfe mara amfani ko kai tsaye zinare, Misali: girma na kauri, babban tari zai haifar da rashin daidaituwa.Tabbas akwai wasu abubuwan da za su iya haifar da irin wannan matsala, duk da haka waɗannan abubuwa biyu sune matsalolin da suka fi yawa.

Akwai rashin amfani guda biyu na rabe bangon rami, na farko ba shakka shine yanayin aiki na gwaji mai tsauri ko tsauri, zai haifar da allon pcb ba zai iya jure damuwa ta jiki ba don ya rabu.Idan wannan matsala yana da wuyar warwarewa, watakila dole ne ku canza kayan laminate don saduwa da ingantawa.

Idan ba shine matsalar da ke sama ba, yawanci saboda ƙarancin mannewa tsakanin ramin tagulla da bangon ramin.Dalilai masu yuwuwa na wannan ɓangaren sun haɗa da rashin isassun bangon rami, kauri da yawa na jan ƙarfe, da lahani na mu'amala da rashin kyawun tsarin aikin tagulla.Wadannan duk dalilai ne mai yiwuwa.Tabbas, idan ingancin hakowa ba shi da kyau, bambancin siffar bangon rami na iya haifar da irin waɗannan matsalolin.Dangane da aikin da ya fi dacewa don magance wadannan matsalolin, ya kamata a fara tabbatar da tushen dalilin sannan a magance tushen dalilin kafin a iya magance shi gaba daya.