Kayan Aikin Taro na PCB

ANKE PCB yana ba da babban zaɓi na kayan aikin SMT wanda ya haɗa da manual, Semi-atomatik da cikakkun firintocin stencil na atomatik, injin ɗaki & wurin da kuma batch ɗin benchtop da ƙananan murhun murhun ƙarar ƙarar juzu'i don taron dutsen ƙasa.

A ANKE PCB mun fahimci inganci shine babban burin taron PCB kuma muna iya cim ma kayan aikin zamani wanda ya dace da sabon ƙirar PCB da kayan haɗin gwiwa.

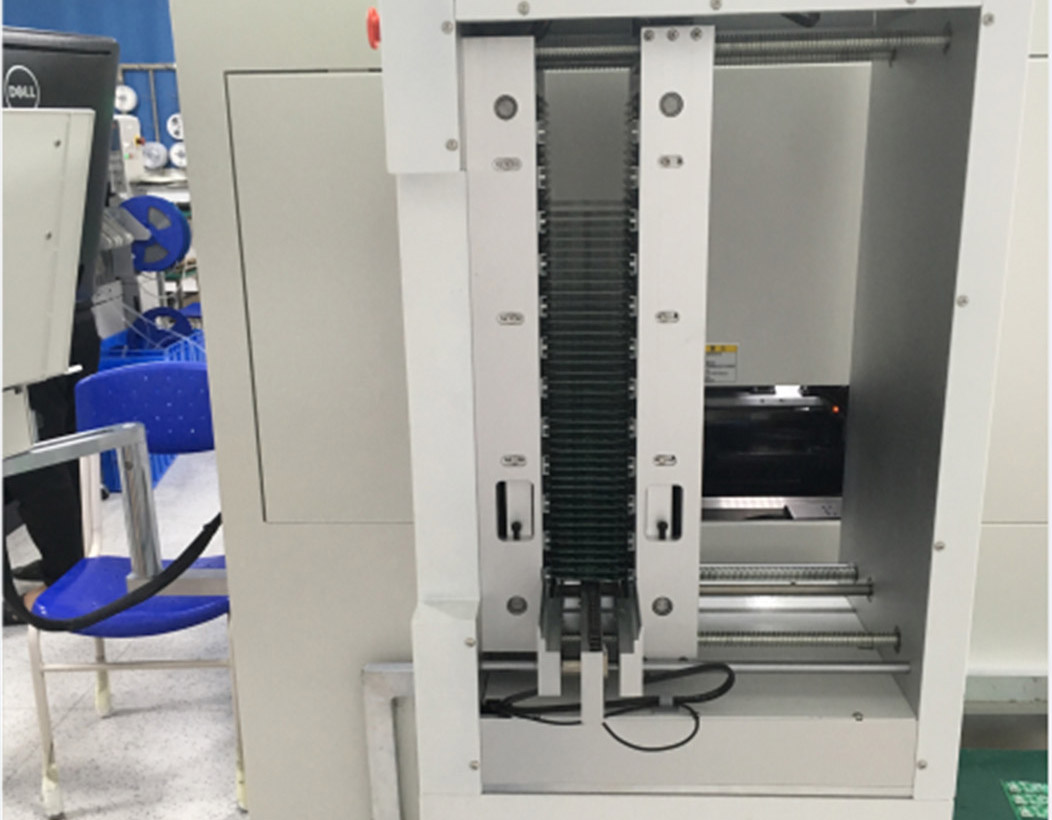

Mai ɗaukar PCB ta atomatik

Wannan injin yana ba da damar allunan pcb don ciyarwa cikin injin bugu na manna ta atomatik.

Amfani

• Adana lokaci don ƙarfin aiki

• Ajiye farashi a cikin samar da taro

Rage kuskuren da zai iya faruwa ta hanyar hannu

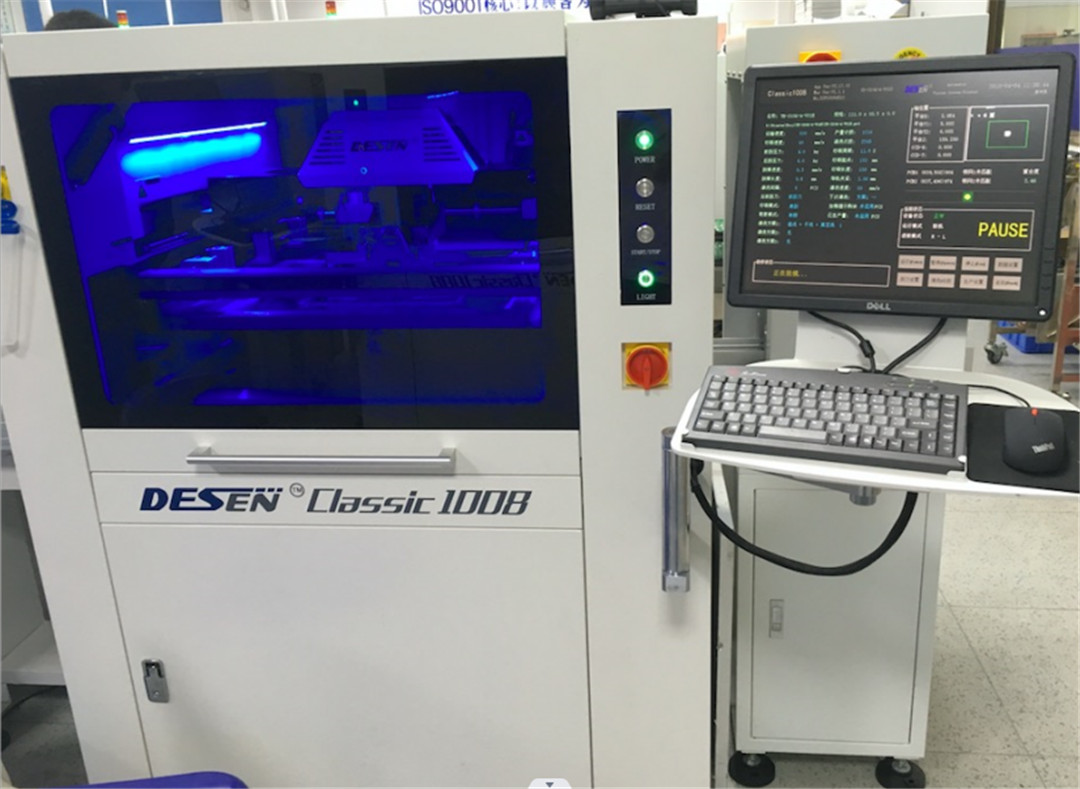

Atomatik Stencil Printer

ANKE yana da kayan aikin gaba kamar na'urorin buga stencil ta atomatik.

• Mai shirye-shirye

• Tsarin squeegee

• Stencil tsarin matsayi na atomatik

• Tsarin tsaftacewa mai zaman kansa

• Canja wurin PCB da tsarin matsayi

• Sauƙi-da-amfani ke dubawa na ɗan adam na Ingilishi/ Sinanci

• Tsarin ɗaukar hoto

• 2D dubawa & SPC

• Daidaiton stencil na CCD

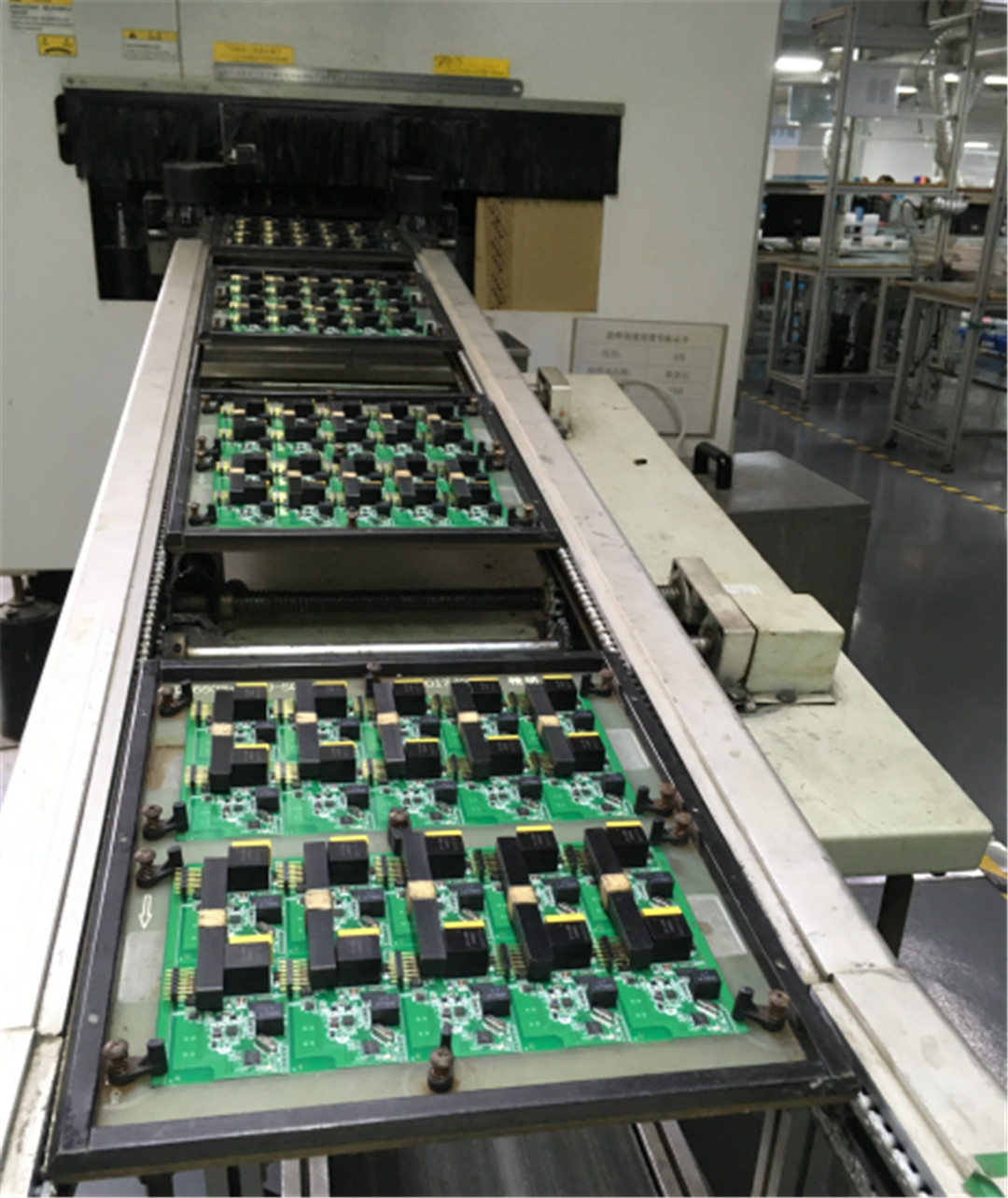

Injin Zaɓi & Wuri na SMT

• Babban daidaito da babban sassauci don 01005, 0201, SOIC, PLCC, BGA, MBGA, CSP, QFP, har zuwa 0.3mm mai kyau

• Tsarin maƙallan linzamin kwamfuta mara lamba don babban maimaitawa da kwanciyar hankali

• Tsarin ciyarwa mai wayo yana ba da duban matsayi na mai ciyarwa ta atomatik, ƙididdige abubuwan atomatik, gano bayanan samarwa

• COGNEX tsarin daidaitawa "Vision on the Fly"

• Tsarin daidaita hangen nesa na ƙasa don kyakkyawan filin QFP & BGA

• Cikakke don ƙarami & matsakaicin girma samar

• Gina-gine tsarin kamara tare da auto smart fiducial mark koyo

• Tsarin rarrabawa

• Binciken hangen nesa kafin da bayan samarwa

• Juyin CAD Universal

• Yawan Wuri: 10,500 cph (IPC 9850)

• Tsarin dunƙule ball a cikin X- da Y-axes

• Ya dace da mai ciyar da tef mai hankali 160

Tanda Mai-Free Mai Gubar Gubar/ Injin Sake Faɗawa Mai Kyau

• Software na aiki na Windows XP tare da madadin Sinanci da Ingilishi.Duk tsarin karkashin

kulawar haɗin kai na iya yin nazari da nuna gazawar.Ana iya adana duk bayanan samarwa gabaɗaya kuma a bincika su.

• PC&Siemens PLC naúrar sarrafawa tare da ingantaccen aiki;Babban madaidaicin maimaita bayanin martaba na iya guje wa asarar samfur wanda aka danganta ga rashin aikin kwamfutar.

• Ƙaƙwalwar ƙira na ƙayyadaddun yanayin zafi na wurare masu zafi daga bangarorin 4 suna samar da ingantaccen zafi mai zafi;Babban bambancin zafin jiki tsakanin sassan haɗin gwiwa 2 zai iya kauce wa tsangwama na zafin jiki;Yana iya rage bambance-bambancen zafin jiki tsakanin manyan-size da ƙananan abubuwan haɗin gwiwa da saduwa da buƙatar siyarwar PCB mai rikitarwa.

• Yin sanyaya iska na tilas ko mai sanyaya ruwa tare da ingantaccen saurin sanyaya ya dace da kowane nau'in manna da gubar kyauta.

• Ƙarfin wutar lantarki (8-10 KWH / awa) don adana farashin masana'anta.

AOI (Tsarin Duban gani Na atomatik)

AOI na'ura ce da ke gano lahani na gama gari a samar da walda bisa ka'idodin gani.AOl fasahar gwaji ce mai tasowa, amma tana haɓaka cikin sauri, kuma masana'antun da yawa sun ƙaddamar da kayan gwajin Al.

Yayin dubawa ta atomatik, injin yana bincika PCBA ta atomatik ta cikin kyamara, tattara hotuna, kuma yana kwatanta mahaɗin solder da aka gano tare da ingantattun sigogi a cikin bayanan.Mai gyara gyara.

Ana amfani da fasahar sarrafa hangen nesa mai saurin gaske, don gano kurakuran jeri daban-daban ta atomatik da lahani na siyarwa akan allon PB.

Kwamfutar PC ta kewayo daga manyan allunan masu girma masu kyau zuwa ƙananan ƙananan allunan girma, suna ba da mafita na dubawa a cikin layi don haɓaka ingantaccen samarwa da ingancin siyarwa.

Ta yin amfani da AOl a matsayin kayan aiki na rage lahani, ana iya samun kurakurai da kuma kawar da su a farkon tsarin taro, wanda ya haifar da kyakkyawan tsarin sarrafawa.Gano lahani da wuri zai hana aika muggan allon allo zuwa matakan haɗuwa na gaba.AI za ta rage farashin gyara kuma ta guje wa goge allunan da ba za a gyara su ba.

3D X-ray

Tare da saurin haɓakar fasahar lantarki, ƙaramin marufi, babban taro mai yawa, da ci gaba da fitowar sabbin fasahohin marufi daban-daban, abubuwan da ake buƙata don ingancin taron kewaye suna samun girma da girma.

Sabili da haka, ana sanya buƙatu mafi girma akan hanyoyin ganowa da fasaha.

Domin biyan wannan buƙatu, sabbin fasahohin dubawa suna ci gaba da kunno kai, kuma fasahar bincikar X-ray ta atomatik na 3D wakili ne na yau da kullun.

Ba wai kawai zai iya gano mahaɗin solder da ba a iya gani ba, kamar BGA (Ball Grid Array, grid array kunshin), da dai sauransu, amma kuma yana gudanar da bincike na ƙididdiga da ƙididdiga na sakamakon ganowa don gano kuskure da wuri.

A halin yanzu, ana amfani da fasahohin gwaji iri-iri a fagen gwajin haɗaɗɗiyar lantarki.

Kayan aiki na yau da kullun sune dubawar gani na Manual (MVI), Gwajin In-Circuit (ICT), da Na gani Atomatik

Dubawa (Dubawar gani ta atomatik).AI), Binciken X-ray na atomatik (AXI), Gwajin Aiki (FT) da sauransu.

Tashar Sake Aikin PCBA

Dangane da tsarin sake yin aiki na gabaɗayan taron SMT, ana iya raba shi zuwa matakai da yawa kamar lalatawa, sake fasalin sassa, tsaftacewa ta PCB, sanya sassa, walda, da tsaftacewa.

1. Rushewa: Wannan tsari shine don cire abubuwan da aka gyara daga PB na ƙayyadaddun abubuwan SMT.Mafi mahimmancin ƙa'ida ba shine lalata ko lalata abubuwan da aka cire da kansu, abubuwan da ke kewaye da pads na PCB ba.

2. Siffar kayan aikin: Bayan an lalata abubuwan da aka sake yin aiki, idan kuna son ci gaba da amfani da abubuwan da aka cire, dole ne ku sake fasalin abubuwan.

3. PCB kushin tsaftacewa: PCB kushin tsaftacewa hada da kushin tsaftacewa da jeri aiki.Matsakaicin pad yawanci yana nufin daidaita saman kushin PCB na na'urar da aka cire.Tsaftace pad yawanci yana amfani da solder.Kayan aikin tsaftacewa, kamar ƙarfe mai siyarwa, yana cire ragowar solder daga pads, sannan yana gogewa da cikakkiyar barasa ko kuma abin da aka amince da shi don cire tara da sauran abubuwan da suka rage.

4. Sanya abubuwan da aka gyara: duba PCB da aka sake yin aiki tare da manna bugu;yi amfani da na'urar sanya kayan aikin tashar sake yin aiki don zaɓar bututun injin da ya dace kuma gyara PCB ɗin sake yin aikin da za a sanya.

5. Soldering: The soldering tsari na rework iya m za a iya raba manual soldering da reflow soldering.Yana buƙatar yin la'akari da kyau dangane da abubuwan da aka haɗa da kaddarorin shimfidar PB, da kuma kaddarorin kayan walda da aka yi amfani da su.Walda na hannu abu ne mai sauƙi kuma ana amfani dashi galibi don sake aikin walda na ƙananan sassa.

Injin Siyar da Wave Mai Kyauta

• Allon taɓawa + naúrar sarrafa PLC, aiki mai sauƙi kuma abin dogaro.

• Ƙirar ƙaƙƙarfan ƙira na waje, ƙirar ƙirar ciki, ba kawai kyakkyawa ba amma kuma mai sauƙin kulawa.

• Mai fesa juyi yana samar da kyakyawan atomization tare da ƙarancin amfani.

• Tubo fan shaye-shaye tare da labulen garkuwa don hana yaɗuwar atomized juzu'i zuwa yankin preheating, tabbatar da aiki lafiya.

• Modularized hita preheating ya dace don kiyayewa;PID kula da dumama, tsayayye zafin jiki, santsi mai lankwasa, warware wahalar tsari mara gubar.

• Solder pans ta amfani da babban ƙarfi, baƙin ƙarfe mara lahani yana samar da ingantaccen yanayin zafi.

Nozzles da aka yi da titanium suna tabbatar da ƙarancin nakasar thermal da ƙarancin iskar shaka.

• Yana da aikin farawa ta atomatik lokaci-lokaci da kashe duk na'ura.