Kaya

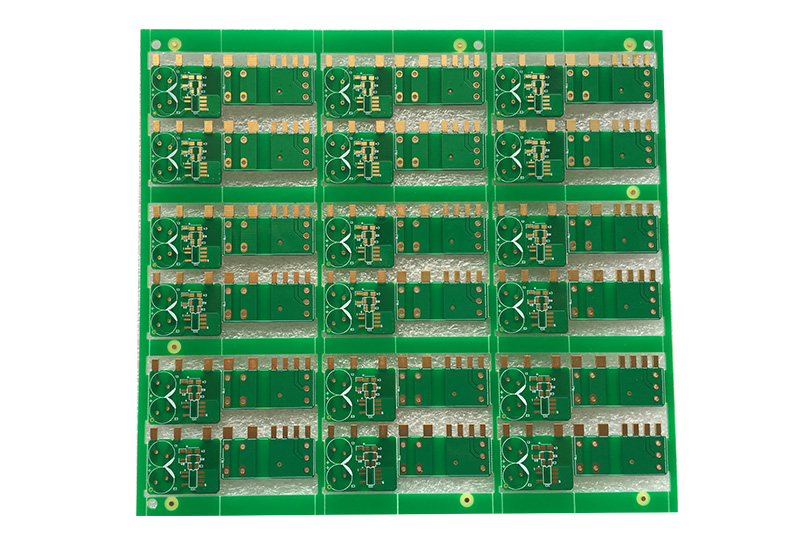

Edge sanya 6 Layer PCB don IOT Babban Hukumar

| Yadudduka | 6 yadudduka 6 |

| Jirgin kauri | 1.60mm |

| Abu | FR4 TG170 |

| Tagaraci | 1/1/1/1/1/1 oz (35um) |

| Farfajiya | Enig au kauri 0.05um; Ni kauri 3um |

| Min rami (mm) | 0.203mm cike da guduro |

| Min layin (MM) | 0.13mm |

| Mana layin (mm) | 0.13mm |

| May | Kore |

| Logen launi | Farin launi |

| Sarrafa inji | V-SCRING, CNC Milling (Routing) |

| Shiryawa | Jakar Anti-Static |

| E-gwajin | Mai Binciken Flying ko tsarawa |

| Standardaya | Ipc-A-600h aji 2 |

| Roƙo | Kayan aikin lantarki na motoci |

Kayan kayan aiki

A matsayina na mai samar da fasahohin PCB, ya kunnawa Zabin lokacin Jagorai, muna da zaɓi na daidaitattun kayan da ke da manyan bandwidth na nau'ikan nau'ikan PCB za a iya rufe su a cikin gida.

Hakanan za'a iya saduwa da wasu ko don kayan musamman a mafi yawan lokuta, amma, dangane da ainihin bukatun, har zuwa kwanaki 10 na aiki ana iya buƙatar samuwa don samo kayan.

Yi tuntuɓe tare da mu kuma ku tattauna bukatunku tare da ɗayan tallace-tallace na tallace-tallace ko ƙungiyar cam.

Tsarin kayan da aka gudanar a cikin jari:

| Abubuwan haɗin | Gwiɓi | Haƙuri | Weave nau'in |

| Yadudduka na ciki | 0,05mm | +/- 10% | 106 |

| Yadudduka na ciki | 0.10mm | +/- 10% | 2116 |

| Yadudduka na ciki | 0,13mm | +/- 10% | 1504 |

| Yadudduka na ciki | 0,15mm | +/- 10% | 1501 |

| Yadudduka na ciki | 0.20mm | +/- 10% | 7628 |

| Yadudduka na ciki | 0,25mm | +/- 10% | 2 x 1504 |

| Yadudduka na ciki | 0.30mm | +/- 10% | 2 x 1501 |

| Yadudduka na ciki | 0.36mm | +/- 10% | 2 x 7628 |

| Yadudduka na ciki | 0,41mm | +/- 10% | 2 x 7628 |

| Yadudduka na ciki | 0,51mm | +/- 10% | 3 x 7628/2116 |

| Yadudduka na ciki | 0,61mm | +/- 10% | 3 x 7628 |

| Yadudduka na ciki | 0.71mm | +/- 10% | 4 x 7628 |

| Yadudduka na ciki | 0,80mm | +/- 10% | 4 x 7628/1080 |

| Yadudduka na ciki | 1,0mm | +/- 10% | 5 x7628 / 2116 |

| Yadudduka na ciki | 1,2mm | +/- 10% | 6 x7628 / 2116 |

| Yadudduka na ciki | 1,55mm | +/- 10% | 8 x7628 |

| -Baya | 0.058mm * | Ya dogara da layout | 106 |

| -Baya | 0.084mm * | Ya dogara da layout | 1080 |

| -Baya | 0.112mm * | Ya dogara da layout | 2116 |

| -Baya | 0.205mm * | Ya dogara da layout | 7628 |

CUHIN kauri don yadudduka na ciki: Standard - 18 Dμ, 35 μm,

A kan bukatar 70 μm, 105μm da 140μm

Nau'in kayan: FR4

TG: Kimanin. 150 ° C, 170 ° C, 180 ° C

εr a 1 mHz: ≤5,4 (hali: 4,7) mafi yawan akan buƙata

Statesup

Babban tsarin saiti na 6 Layer zai kasance gaba ɗaya kamar yadda ke ƙasa:

· Top

Na ciki

Ƙasa

· Ikon

Na ciki

Ƙasan

Tambaya

Yadda za a gwada ramin bango na rami da kuma ƙayyadaddun bayanan da suka shafi? Garin rami ya cire abubuwan da ke haifar da mafita?

Anyi amfani da gwajin jan rami a baya ga-rami sassa don haduwa da bukatun taro. Janar gwajin shine sayar da waya a kan PCB Board ta hanyar ramuka sannan kuma auna darajar fitar da mitar. Ya Yarda da Kwarewa, Darajojin gaba ɗaya suna da girma sosai, wanda ya sa kusan babu matsaloli a aikace-aikace. Bayanin samfurin ya bambanta da

Ga buƙatu daban-daban, ana bada shawarar magana game da takamaiman bayanan da suka shafi IPC.

Matsalar rarrabuwa bango matsala ita ce batun rashin ƙarancin rashin tausayi, wanda dalilai biyu ne ke haifar da tashin hankali ba su isa ba. Sauran shi ne tsarin jan karfe na lantarki ko zinari kai tsaye, alal misali: haɓakar lokacin farin ciki, tari mai girma zai haifar da talauci m. Tabbas akwai wasu dalilai masu iya tasiri irin wannan matsalar, duk da haka waɗannan abubuwan guda biyu sune matsaloli mafi yawancin matsaloli.

A can akwai abubuwan da suka lalace biyu na rabuwar rami, na farko da na farko shine yanayin aikin PCB ba zai iya tsayayya da damuwa ba, zai iya rabuwa da damuwa. Idan wannan matsalar tana da wahala a warware, wataƙila dole ne ku canza kayan shimfiɗaɗɗiya don biyan ƙarin.

Idan ba matsalar da ke sama ba ce, mafi yawa saboda rashin tabbatacciyar adhesion tsakanin jan ƙarfe da katangar ramin. Dalilin da zai yiwu a wannan bangare sun hada da isasshen ramuwar dutse, kauri mai kauri na magani mai sarrafawa. Waɗannan duka abin yiwuwa ne. Tabbas, idan ingancin hakowa ba shi da kyau, siffar canjin bangon ramin na iya haifar da irin matsaloli. Amma ga mafi mahimmancin aikin don magance waɗannan matsalolin, ya kamata ya fara tabbatar da tushen dalilin sannan a magance tushen sanadin da aka samu kafin a iya warware shi.