PCB kwamitinDokoki da Hanyoyi

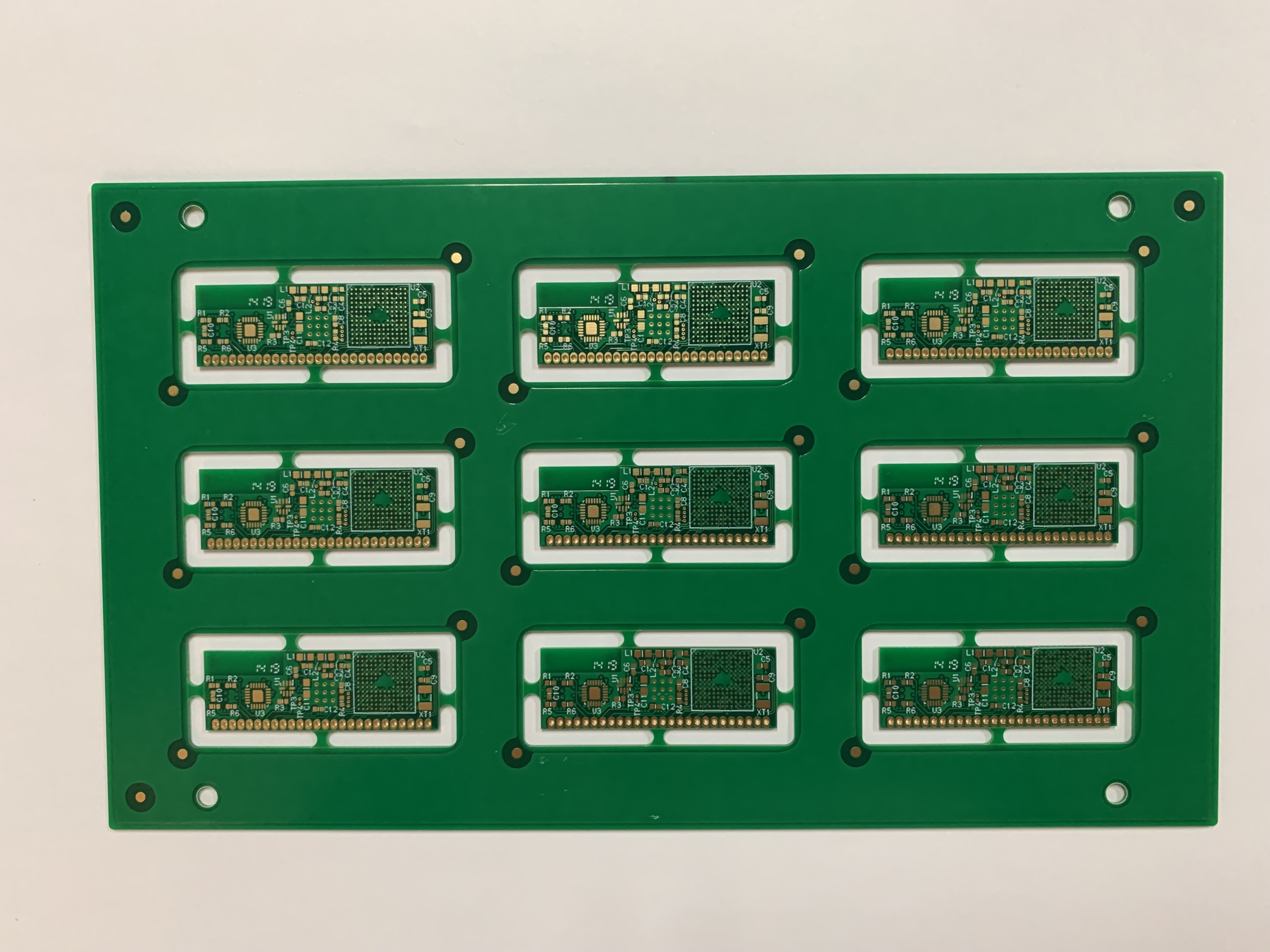

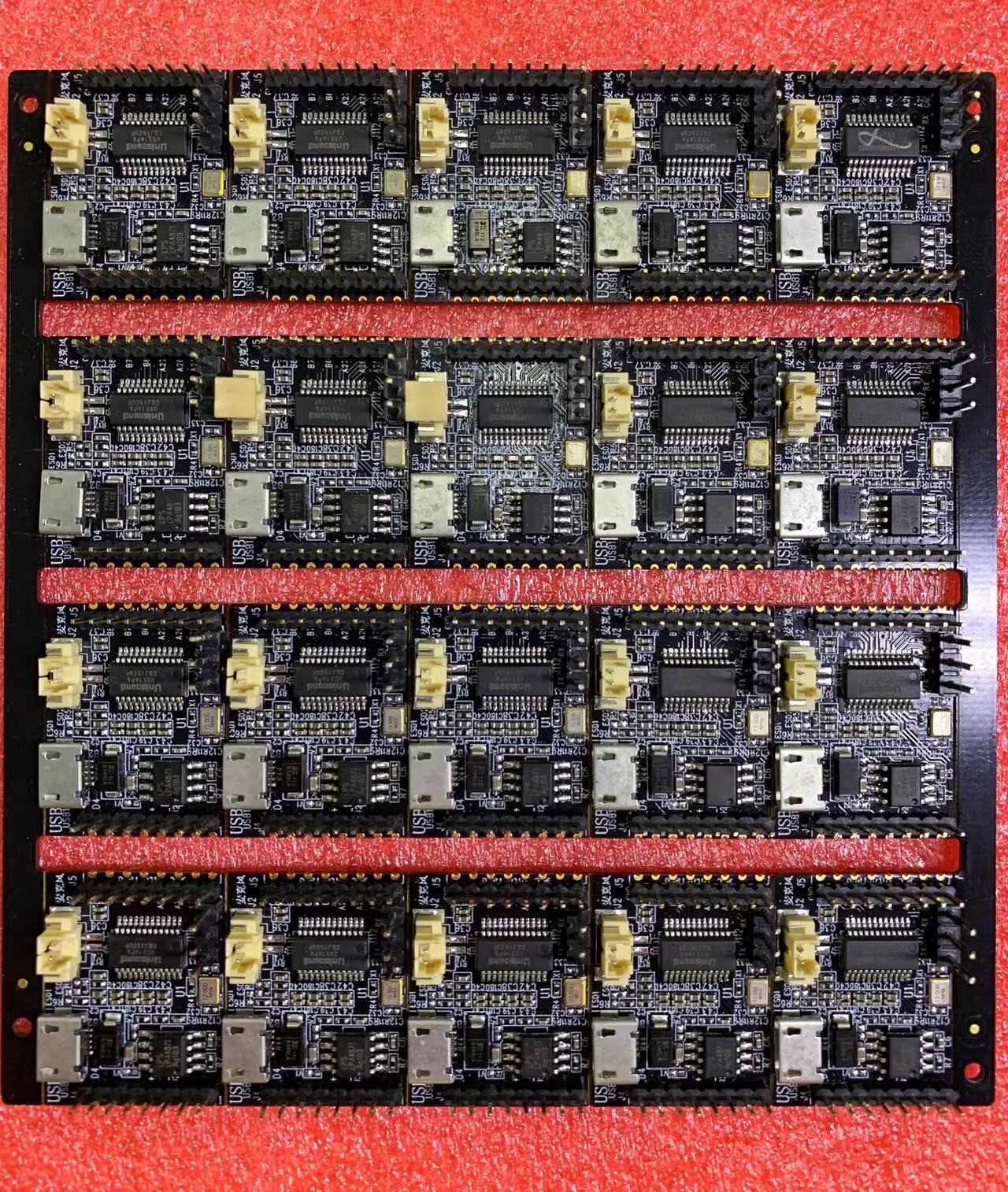

1. Dangane da ka'idojin aikin masana'antu daban-daban, matsakaicin girman da girman girman kwamitin ya kamata a fili ya fahimta. Gabaɗaya, PCB ƙarami fiye da 80x80mm bukatar a fallacized, kuma matsakaicin girman ya dogara da ƙarfin aiki na masana'antar. A takaice, girman PCB yakamata ya cika buƙatunSMT kayan aikiFitings, wanda ke da dacewa a smt Patch aiki da taimako don yanke shawarar kauri daga cikin kwamitin PCB.

2. Dole ne Majalisar da kuma shiga cikin jirgin sun cika bukatun DFM da DFA, kuma a lokaci guda tabbatar da cewa an daidaita taron PCB kuma ba a sauƙaƙe taro bayan an sanya shi bayan an sanya shi a farfajiyar. Rage tsagi tsakanin bangarorin ya kamata su cika bukatun da ke tattare da farfajiyar a lokacinPcbaCanja kan guntu.

3. A cikin PCB Panelzane, tsarin abubuwan haɗin ya kamata su guji rarrabuwar damuwa da kuma haifar da fasa kayan fasaho. Amfani da tsarin panes na panes na iya rage warpage da nakasa yayin rabuwa, da rage damuwa a kan abubuwan da ke ciki. Zuwa m, yi kokarin kar a sanya mahimmanciAbubuwan haɗindaga nanzuwa tsarin gudanarwa.

4. Girman girman da nau'i na panel an sarrafa bisa ga takamaiman aikin, kuma ƙirar bayyanar tana kusa da murabba'i-wuri. An bada shawara sosai don amfani da 2 × 2 ko 3 × 3 Hanyar Panes. Ba'a ba da shawarar haɗuwa da yang da yang idan ba lallai ba ne;

5. Lokacin da batun haɗin gwiwar Biliya ya wuce tsoma baki tsakanin allon haɗin gwiwa tsakanin katako, an warware shi ta hanyar jujjuyawar iyakar haɗari yayin watsa ko tsaribayan waldi.

6. Bayan ƙirar Panel, dole ne a tabbatar da cewa gefen ƙarshen matakin babban kwamitin akalla 3.5mm) daga gefen kwastomomi guda biyu akan babban jirgi ba za a iya sanya shi da yawa ba. Kada a sanya maki mai ma'ana daidai, saboda juyar da baya / juye na PCB na iya shigar da injin ta hanyar aikin na'urar da kanta.

7. Lokacin da kauri daga cikinKwamiti na PCBKasa da 1.0mm, ƙarfin hukumar kwamitin gaba daya za a kara shi sosai a lokacin da tsintsiya ta V-yanke. Idan Jigo ba ne ke tallafawa ba, zai shafi tsari a kasa da PCBA.

8. Lokacin da akwaiyatsun zinareA PCB, gaba ɗayan yatsan gwal a waje da hukumar ta hanyar gefen matsayin da ba. Gefen yatsan gwal na zinariya ba zai iya sarrafawa ba ko sarrafa shi.

Shenzhen Anke PCB Co., Ltd

Lokaci: Apr-04-2023