Kaya

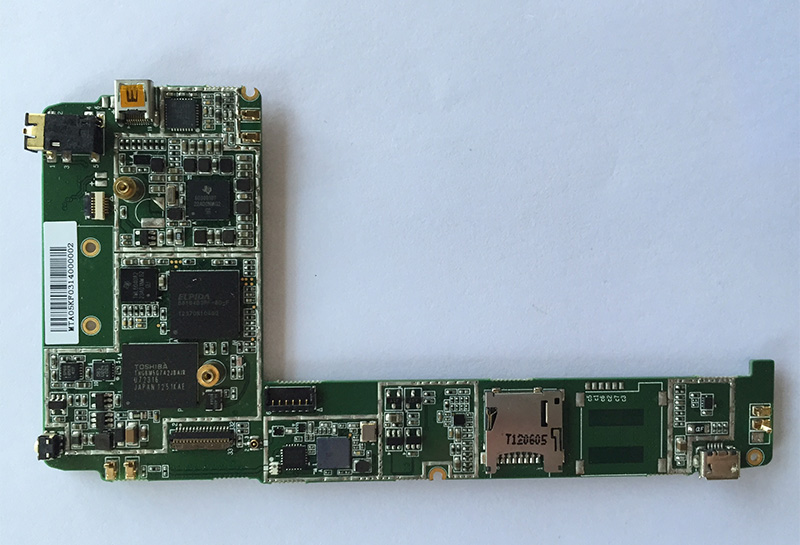

PRICOM PRICOMPLADEL SARKIN KYAUTA

Wannan aikin Majalisar IM PCB ne don babban adadin wayar saler. Masu amfani da kayan lantarki, daga samfuran Audio ga masu siye, caca ko ma gaskiya ne na gaskiya, duk ana samun ƙarin haɗin kai. Duniyar dijital muna rayuwa a cikin buƙatar babban matakin haɗi da haɓaka lantarki da ƙarfin lantarki, mu, a Annke, a cikin Ann Anontive Pt Worldwide.as, a Annkeotive Pica Masana'antu, ƙimar PCBA, a cikin Andototive Averystonia, ƙira da kuma prototyy.

| Yadudduka | 10 yadudduka |

| Jirgin kauri | 0.8mm |

| Abu | Shengyi S1000-2 FR-4 (TGEW170 ℃) |

| Tagaraci | 1oz (35um) |

| Farfajiya | Enig au kauri 0.8um; Ni kauri 3um |

| Min rami (mm) | 0.13mm |

| Min layin (MM) | 0.15mm |

| Mana layin (mm) | 0.15mm |

| May | Kore |

| Logen launi | Farin launi |

| Girman Bada | 110 * 87mm |

| PCB Majalisar | Gauraya dutsen dutsen zuwa bangarorin biyu |

| Rohs ya cika | Jagoranci Majalisar Daidaitawa |

| Mafi qarancin kayan aikin | Mai -201 |

| Jimlar bangarorin | 677 a kowace jirgi |

| Ic fafful | BGA, QFN |

| Babban ic | Kalmomin Texas, Toshiba, a kan Semiconductor, Farrichild, NXP, St, Linear |

| Jarraba | Aoi, X-Ray, Gwajin Aiki |

| Roƙo | Mai watsa labutan lantarki |

Tsarin Majalisar SMT

1. Wuri (curing)

Matsayinta shine narke mai ɗaukar hoto wanda ya sa a saman dutsen da saman saman, an haɗa kwamitin PCB tare.

Kayan aikin da aka yi amfani da shi shine murhun tanda, wanda ke bayan injin wuri a cikin layin SMT.

2. Sake sake

Matsayinta shine a narke mai sayar da hayaƙi, wanda ya sa dutsen ya gina kayan samaniya da kuma kwamitin PCB an haɗa shi tare. Kayan aikin da aka yi amfani da shi shine tanda na gama gari, wanda ke bayan murfin.

Mutu akan layin SMT.

3. SMT Majalisar Tsabtarwa

Abin da ake yi shine cire sharan siyarwa kamar UX

PCB ɗin ya tattara yana cutar da jikin ɗan adam. Kayan aikin sun yi amfani da injin wanki, wurin na iya zama

Ba a gyara ba, yana iya zama kan layi ko layi.

4. Sanarwar Majalisar SMT

Aikinsa shine a bincika waldi da ingancin taro

Hukumar PCB ta tattara.

Kayan aikin da aka yi amfani da shi ya hada da gilashin girma, micctcope, a cikin-da'ira ta-da'ira, da kuma dubawa na tsaye (AOI), tsarin dubawa na atomatik, da sauransu, da sauransu.

5. Majalisar SMT

Matsayinta shine sake dawo da jirgi na PCB

Kuskure. Kayan aikin da aka yi amfani da su ana sayar da kayan ƙarfe, tashar sake aiki, da sauransu.

ko'ina akan layin samarwa. Kamar yadda ka sani, akwai wasu ƙananan batutuwan yayin samarwa, don haka taron retworm mai aiki shine hanya mafi kyau.

6. SMT Majalisar Caka

PCBMY yana ba da taro, farfewar al'ada, yin ɗalibin ruwa, ɗakunan ruwa da sauran mafita don samar da cikakken mafita don bukatun kamfanin.

Ta amfani da atomatik don tattarawa, kunshin kuma tabbatar da samfuranmu, zamu iya samar wa abokan cinikinmu tare da mafi ingantaccen samarwa.

Mai ba da sabis na sabis na lantarki don motoci, muna rufe aikace-aikace da yawa:

> Samfurin Kayan Aiki

> Yerial & zafi mai zafi

> Fightleight

> Hasken Smart

> Modules ikon

> Masu Gudanar da Kafaffuna & Great

> Kamfanin sarrafa jikin mutum

> Gudanar da makamashi

Na uku, farashin ya bambanta saboda rikitarwa da yawa.

PCB zai zama tsada daban-daban koda kuwa kayan da tsari iri ɗaya ne, amma tare da rikitarwa daban-daban. Misali, idan akwai ramuka 1000 akan allon allo, rami diamita na daya ya fi na 0.6mm. Idan allon allo biyu iri daya ne a wasu buƙatun, amma layin layi daban ne ma ya fi tsada girma sama da 0.2mm. Saboda allon da ƙasa da 0.2mm suna da ƙimar ƙarancin sakamako, wanda ke nufin farashin samarwa ya fi na al'ada.

Na hudu, farashin ya bambanta saboda bukatun abokin ciniki daban-daban.

Abubuwan buƙatun abokin ciniki zai shafi kai tsaye da rashin nasara a samarwa. Irin wannan kwamiti da IPC-A-600e Class1 na bukatar kashi 98% Sassin 90% na buƙatar canje-canje na 90% don masana'antar a farashin kaya.