Kaya

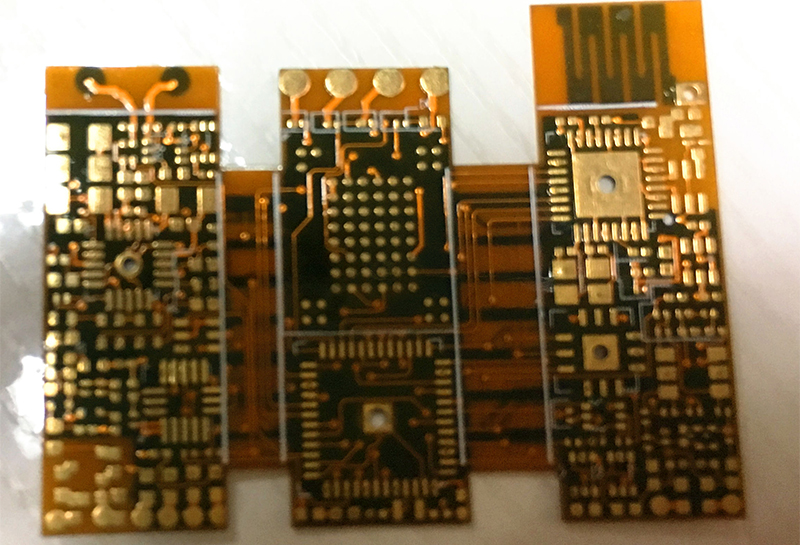

4 Layer FPC tare da Fr4 Squiffener a cikin 4G Module

| Yadudduka | 4 yadudduka masu flow |

| Jirgin kauri | 0.2Mm |

| Abu | Polymide |

| Tagaraci | 1 oz (35um) |

| Farfajiya | Enig au farin ciki 1um; Ni kauri 3um |

| Min rami (mm) | 0.23mm |

| Min layin (MM) | 0.15mm |

| Mana layin (mm) | 0.15mm |

| May | Kore |

| Logen launi | Farin launi |

| Sarrafa inji | V-SCRING, CNC Milling (Routing) |

| Shiryawa | Jakar Anti-Static |

| E-gwajin | Mai Binciken Flying ko tsarawa |

| Standardaya | Ipc-A-600h aji 2 |

| Roƙo | Kayan aikin lantarki na motoci |

Shigowa da

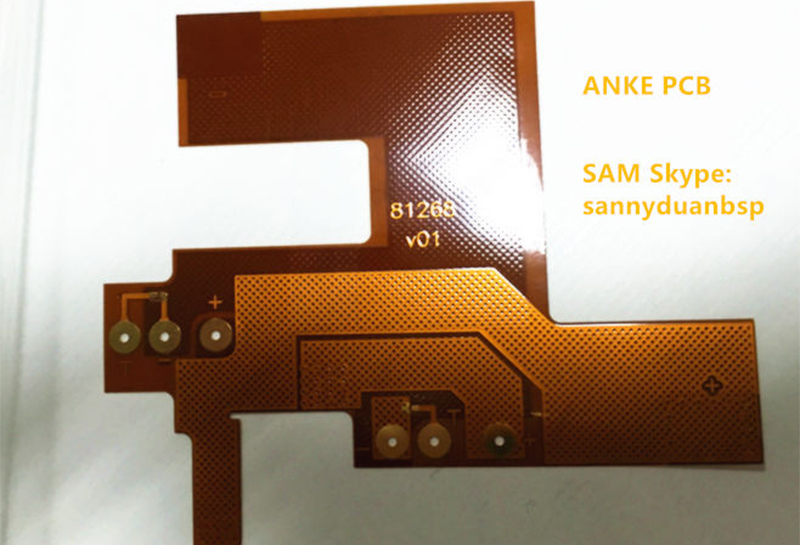

Flight PCB wani yanki ne na musamman na PCB wanda zaku iya lanƙwasa cikin siffar da ake so. Ana amfani da su yawanci don babban yawa da ayyukan zafin jiki sosai.

Saboda kyakkyawan juriya mai zafi, ƙirar sassauƙa tana da kyau ga abubuwan haɗin soja. Fim ɗin Polyester mai ban sha'awa wanda aka yi amfani da shi wajen gina zane zane mai amfani yana aiki kamar kayan abu.

Kuna iya daidaita kauri na tagulla daga 0.0001 "zuwa 0.010", yayin da kayan masu sata zasu iya kasancewa tsakanin 0.0005 "da 0.00010" lokacin farin ciki. Karuwa a cikin hada-hada a cikin m zane.

Saboda haka, akwai karancin haɗin haɗin kai. Bugu da ƙari, waɗannan da'irori suna ɗaukar kashi 10% kawai na sararin samaniya

Saboda raunin da suka canza.

Abu

Ana amfani da sassauƙa da kayan masarufi don ƙera samfuran samfuri masu sassauza. Sassaucinsa yana ba shi damar juyawa ko motsawa ba tare da lalacewar lalacewa ba ga abubuwan haɗinsa ko haɗi.

Duk wani bangare na pcb pcb dole ne ya kasance mai tasiri. Kuna buƙatar kayan abubuwa daban-daban don tara katako.

Rufe Layer substrate

Mai sanya hannun jari da maɓallin rufewa ƙayyade aikin substrate da fim. Bugu da ƙari, dole ne ya zama dole ya lanƙwasa da curl.

Polyimide da zanen polyester ana amfani da su a cikin sassauƙa sassauƙa. Waɗannan kaɗan ne daga fina-finai da yawa na polymer waɗanda zaku samu, amma akwai ƙarin ƙarin zaɓi.

Zabi ne mafi kyau saboda ƙarancin farashi da kuma substrate mai ƙarfi.

Pi Pilyimide shine kayan da aka fi amfani dasu ta hanyar masana'antun. Wannan nau'in resin na thermostatic zai iya tsayayya da matsanancin yanayin zafi. Don haka narkewa ba matsala. Bayan polymerization, har yanzu yana riƙe da elasticity da sassauƙa. Baya ga wannan, yana da kyawawan kaddarorin lantarki.

Kayan sarrafawa

Dole ne ku zaɓi kashi na shugaba wanda ke canja wurin iko mafi inganci. Kusan dukkanin tabbacin fashewar fashewar suna amfani da jan ƙarfe kamar yadda shugaba na farko.

Bayan kasancewa mai kyau mai kyau, jan ƙarfe ma yana da sauƙin samu. Idan aka kwatanta da farashin sauran kayan aikin, ciniki ne na ciniki. Aikin bai isa ya hana zafi yadda ya kamata ba; Hakanan dole ne ya zama kyakkyawan mai jagoranci. Za'a iya yin sassauci mai sassauƙa ta amfani da kayan da ke rage zafin da suke haifar da wuta.

Adheresives

Akwai wani m tsakanin takarda polyimide da jan ƙarfe a kowane katako mai da'ira. Epoxy da acrylic sune manyan adhere guda biyu da zaka iya amfani da su.

Ana buƙatar adon adheres don magance babban yanayin zafi da aka samar da tagulla.