Kaya

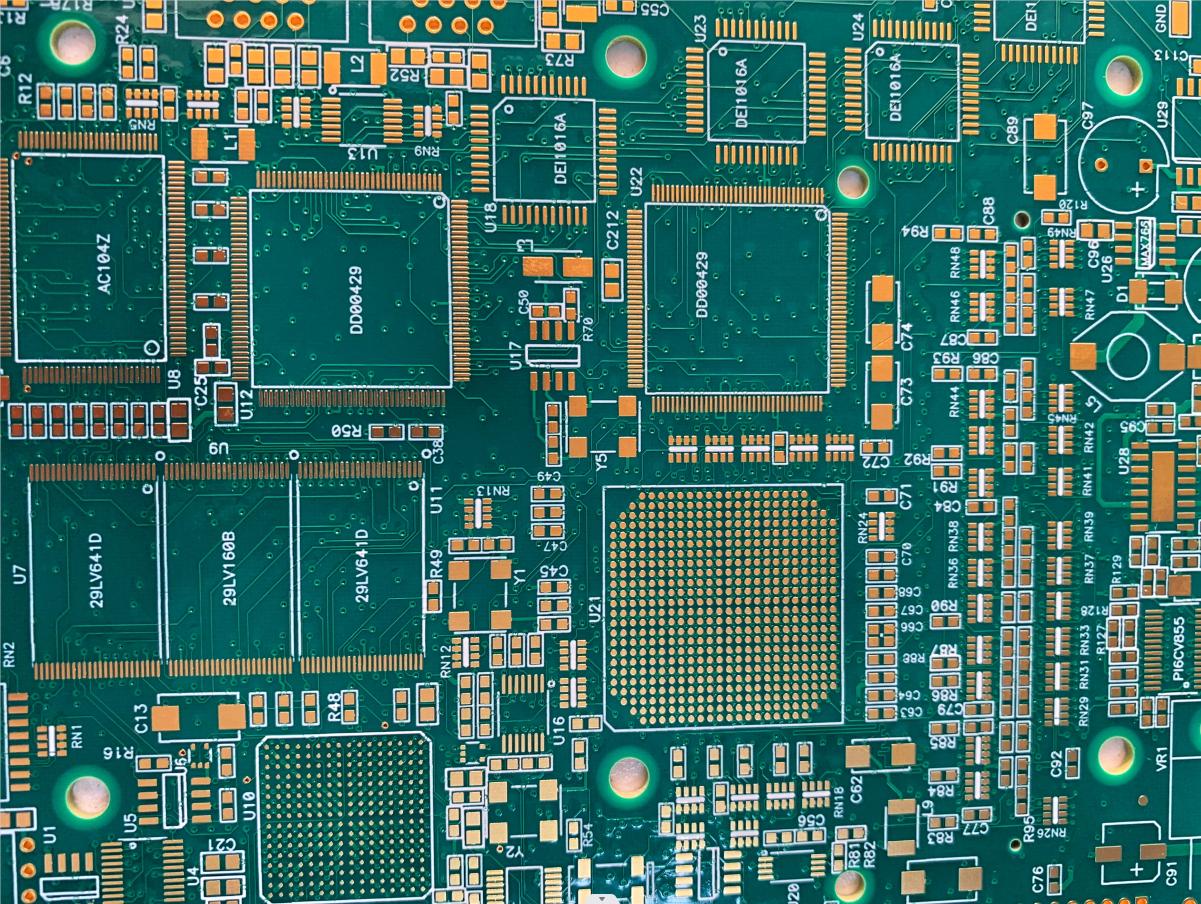

18 Layer HDI don sadarwa tare da oda na musamman da oda

| Yadudduka | 18 yadudduka |

| Jirgin kauri | 1.58MM |

| Abu | FR4 TG170 |

| Tagaraci | 0.5 / 1/1 / 0.5 / 0.5 / 1/1 / 0.5 / 0.5 / 1/1 / 0.5oz |

| Farfajiya | Ansa da kauri0.05um; Ni kauri 3um |

| Min rami (mm) | 0.203mm |

| Min layin (MM) | 0.1mm/ 4mil |

| Mana layin (mm) | 0.1mm/ 4mil |

| May | Kore |

| Logen launi | Farin launi |

| Sarrafa inji | V-SCRING, CNC Milling (Routing) |

| Shiryawa | Jakar Anti-Static |

| E-gwajin | Mai Binciken Flying ko tsarawa |

| Standardaya | Ipc-A-600h aji 2 |

| Roƙo | Kayan aikin lantarki na motoci |

Shigowa da

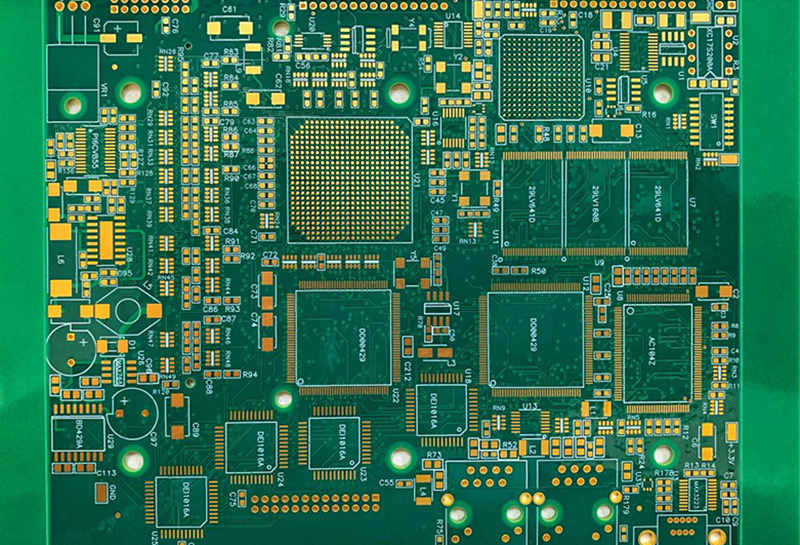

HDI wani raguwa ne ga masu haɗin gwiwa mai yawa. Halittar zane mai zane ne mai hade. Fasahar HDI PCB zata iya rage allon katako a cikin filin PCB. Fasaha ta samar da babban aiki da kuma yawan yawa na wayoyi da da'irori.

Af, an tsara allon HDI daban-daban fiye da na al'ada buga da'irar allon.

HDI PCBs suna da iko ta karami ta vas, layin da sarari. HDI PCBBs suna da nauyi sosai, wanda yake da alaƙa da manya.

A gefe guda, HDI ana nuna shi ta hanyar watsa mitsi, sarrafawa mai sassaucin ra'ayi, da kuma sarrafa rashin daidaituwa akan PCB. Sakamakon karamin jirgin, dadarin kwamitin yana da yawa.

Microviiya, Makaƙa da aka binne waƙoƙi, babban aiki, kayan bakin ciki da kyawawan layin sune duk allo na allon katako.

Dole ne injiniyan dole ne su fahimci cikakkiyar fahimta game da tsarin ƙirar da tsarin masana'antar masana'antu na HDI. Microchips akan HDI buga da'irar allon suna buƙatar kulawa ta musamman a cikin babban taron, da kuma ingantacciyar ikon sarrafa.

A cikin babban tsari kamar kwamfyutoci, wayoyin hannu, kwamfutar hannu pcbs sune karami a girma da nauyi. Saboda karancin girman su, HDI PCBs suma suna da ƙarancin ƙarfin fasa.

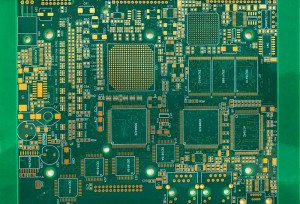

HDI Vias

Vias suna ramuka a cikin PCB wanda ake amfani da shi don haɗa yadudduka daban-daban na lantarki a cikin PCB. Ta amfani da yadudduka da yawa da haɗa su da vias yana rage girman PCB. Tunda babban burin kwamitin HDI shine ya rage girmansa, ta hanyar daya daga cikin mahimman dalilai ne. Akwai nau'ikan nau'ikan abubuwa daban-daban.

THoro rami ta hanyar

Ya shiga cikin gaba ɗaya pcb, daga farfajiya na farfajiya zuwa kasan ƙasa, kuma ana kiranta ta. A wannan gaba, sun haɗu da dukkan yadudduka na buga allo. Koyaya, vias dauki ƙarin sarari da rage sararin samaniya.

Makahota

Makaho Vias kawai haɗa waje na waje zuwa murfi na ciki na PCB. Babu buƙatar rawar da dukan PCB.

An binne ta Via

Ana binne Vias don haɗa yadudduka na ciki na PCB. Aka binne Vias ba a bayyane daga waje na PCB.

Microta

Micro Vias sune mafi ƙanƙanci ta girman girman ƙasa da mil 7. Kuna buƙatar amfani da laser hakoma don samar da micro vas. Saboda haka m, microsvias ana amfani dashi don allon HDI. Wannan saboda girman sa ne. Tunda kuna buƙatar sernity sarai kuma ba zai iya bata sarari a cikin HDI PCB ba, yana da hikima a maye gurbin wasu vias gama gari tare da micraitias. Bugu da ƙari, microsvias ba sa fama da batutuwan fadada yanayin sararin samaniya (cte) saboda gajarta harsunan su.

Statesup

HDI PCBC-Upungiyar Layer-by-Kungiyar Layer. Yawan yadudduka ko lands za'a iya ƙaddara kamar yadda ake buƙata. Koyaya, wannan na iya zama yadudduka 8 zuwa yadudduka 40 ko fiye.

Amma ainihin adadin yadudduka ya dogara da yawan wuraren burbushi. Mullila na mullla na iya taimaka muku rage girman PCB. Hakanan yana rage farashin masana'antu.

Af, don sanin adadin yadudduka akan HDI PCB, kuna buƙatar sanin girman da alama da raga akan kowane Layer. Bayan gano su, zaka iya lissafin cakulan Layashin da ake buƙata don hukumar HDI.

Shawara don tsara HDI PCB

1. Daidai wani zaɓi. Board din HDI yana buƙatar babban lambar PIN da BGAS ƙarami fiye da 0.65mm. Kuna buƙatar zaɓan su cikin hikima kamar yadda suke shafar ta hanyar nau'in, gano nisa da HDI PCB-up.

2. Kuna buƙatar amfani da microvias akan hukumar HDI. Wannan zai ba ku damar samun sau biyu sararin tai ko wani.

3. Abubuwan da ke da inganci da inganci dole ne a yi amfani da su. Yana da matukar muhimmanci ga masana'antun samfurin.

4. Don samun Flat PCB surface, ya kamata ka cika ramuka na ta hanyar ramuka.

5. Yi ƙoƙarin zabar kayan tare da ragin kuɗi iri ɗaya don duk yadudduka.

6. Bayar da hankali sosai ga sarrafa zafi. Tabbatar tsara yadda yakamata kuma shirya yadudduka waɗanda zasu iya hana zafi sosai.